Press

The Piranha-Whitney combination is consistently better than lasers, plasma machines and water jet machines in terms of ROI, even as laser technology improves to cut thicker pieces faster. The Punch Plasma Combination will place more parts on the floor in steel, stainless and aluminum than any other process.

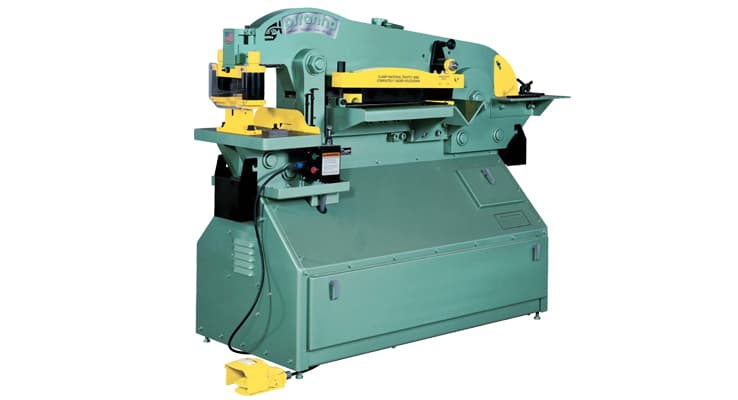

On-line, you can find specifications and capacities for all of our presses. You are welcome to contact us with any questions or to help you find the best solution to your problems.